- Powder Coating

- Sand Blasting

- Laser Cleaning

- Floor Coating

- Wet Painting

- Kolsterised Surface Treatment

- Metal Roofing

- Teflon / PTFE Coating

VITRAKUKUH SDN BHD

Permatang Tinggi Branch (Powder Coating)Lot 20055A, Kampung Manggis, Permatang Tinggi, 14000 Bukit Mertajam, Penang, Malaysia.

+6012-405 5977

+6017-476 7828

+6017-476 7828

+60174767828

Juru Branch (Metal Roofing)

TS1182N/TO, Jalan Kebun Baru, Juru Estate, 14000 Bukit Mertajam, Penang,Malaysia.

+6012-440 8828

+6017-464 5977

+6019-423 9555

+6017-464 5977

+6019-423 9555

Our Services

Powder Coating (13) View More | |||

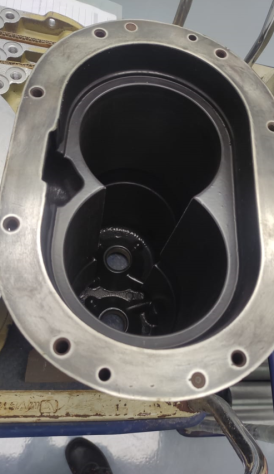

Powder coating is the process of applying dry powder substance to metal objects instead of using normal wet paint. Vitrakukuh employs a technologically advanced and efficient method of powder coating for a perfect surface finishing. Powder coating is an efficient way to finish a steel or non-steel substrate as it does not require drying times and importantly, it does not drip or sag, thus leading to clean cut satisfactory results. It leads to a durable finish that is also resistant to corrosion, heat, impact and abrasion. In every powder coating process, surface preparation is an important first step to remove oil, grease, metal oxides and other chemicals from the metal. It is after the metal is stripped and ready, the application of dry powder will start to produce a smooth, durable and corrosion-resistant finishing. Finally, the product will be cured at a certain temperature and length of time to strengthen the coating for a more lasting effect.  | |||

KOSKOTE EP-SERIES |  KOSKOTE 4040 HY-SERIES |  KOSKOTE 4030 HY-SERIES |  KOSKOTE 4020 HY-SERIES |

Vitrakukuh offers sand blasting services offsite and onsite, at our customers' convenience, using its state-of-the-art blasting equipments. The company is fully equipped coupled with highly professional and experienced workers to conduct industrial and commercial blasting for various materials. Sand blasting will serve to maximise the service life of equipments which will reduce downtime for companies that rely of these equipments.  | |||

sandblasting |  sandblasting |  sandblasting |  Sand Blasting |

Vitrakukuh provides laser cleaning service for surface cleanliness, can remove the resin, oil contamination, stains, dirt, rust, coating, plating and paint on the surface of different shape metal objects, and the stone caving surface attachments and rubber mould surface residue. | |||

Laser Service |  Laser Service |  Laser Service |  Laser Service |

A good flooring system is essential for a safe and comfortable working environment. At Vitrakukuh, we provide clients with the best possible flooring solutions. | |||

Floor Coating |  Floor Coating |  Floor Coating | |

Vitrakukuh provides wet paint spraying services and can be used on all kinds of metal work. | |||

Wet Painting |  Wet Painting |  Wet Painting | |

Kolsterising is not a coating but a low-temperature surface carbon diffusion treatment that enhances the hardness of an alloy 4-5 times that of the base material. The process adds large concentrations of carbon atoms that form high compressive stresses on the surface. Kolsterising is a low temperature, thermo-chemical, diffusion-based surface hardening technology that is used to enhance the inherently poor mechanical and tribological properties of austenitic stainless steels, according to Derek Dandy, a medical market development engineer at Bodycote. It can be used on stainless steels, cobalt and nickel-based alloys, offering hardness and improved mechanical and wear properties without corrosion resistance loss.  | |||

Kolsterised Surface Treatment |  Kolsterised Surface Treatment |  Kolsterised Surface Treatment |  Kolsterised Surface Treatment |

Metal Roofing (11) View More | |||

V PANEL |  SUNROOF |  C PURLIN |  V CAP |

Teflon non-stick industrial coatings are available in both liquid and powder. The versatility of Teflon coatings allow almost unlimited application to a wide variety of parts sizes and configurations, always adding value far beyond the inherent non-stick qualities. Versatility unmatched by any other engineered material. Industrial Teflon coatings spray on like paint and bake to a tough, inert finish. By combining heat resistance with almost total chemical inertness, excellent dielectric stability and a low coefficient of friction, non-stick industrial coatings offer a balance of properties unbeatable by any other material. With an industrial Teflon coating, the coefficient of friction is generally lowered to a range of 0.02 to 0.15, depending on the load, sliding speed, and type of coating used. Dry lubricant coatings are special versions of Chemours technology designed to provide lubrication under high-pressure/velocity (PV) conditions. These products are solvent-based, one-coat systems that are usually cured between 148°C/300°F and 371°C/700°F. Teflon coating services can be applied to carbon steel, aluminium, stainless steel, steel alloys, brass and magnesium as well as non-metallics such as glass, fiberglass, some rubber and plastics. Optimum adhesion is obtained by roughening the surface before applying the industrial coating. | |||

Teflon Coating |  Teflon Coating |  Teflon Coating |  Teflon Coating |